Ingqiqo esisiseko yoshicilelo

1. Ushicilelo: Inkqubo yokuprinta iipateni zeentyatyambo ezinokukhawuleza okuthile kokudaya kwiilaphu ezinedayi okanye ii-pigments.

2. Ukuhlelwa kweeprints

Into yoshicilelo ikakhulu ilaphu kunye nomsonto. Owangaphambili udibanisa iphethini ngokuthe ngqo kwilaphu, ngoko ke ipateni icace ngakumbi. Oku kokugqibela kukushicilela ipateni kwingqokelela yeentambo ezicwangciswe ngokunxuseneyo, kwaye uthunge ilaphu ukuvelisa isiphumo sepateni emdaka.

3. Umahluko phakathi kokuprinta kunye nokudaya

(1) Ukudaya kukudaya ngokulinganayo kwilaphu ukuze ufumane umbala omnye. Ukuprintwa kukuprintwa kombala omnye okanye ngaphezulu kwipatheni ye-textile efanayo, enyanisweni, ukudaya kwendawo.

2 Ukushicilela ngoncedo lwe-slurry njengendlela yokudaya, idayi okanye i-pigment printing paste eprintiweyo kwilaphu, emva kokumisa, ngokuhambelana nohlobo lwedayi okanye umbala wokutshisa, ukunikezelwa kombala kunye nolunye unyango olulandelayo, ukuze idayiwe okanye igxininiswe kwifayibha, kwaye ekugqibeleni emva kwesepha, amanzi, ukususa i-agent edadayo kumbala kunye nombala wepeyinti.

4. Unyango phambi kokuba uprinte

Ngokufana nenkqubo yokudaya, ilaphu kufuneka liphathwe kwangaphambili ngaphambi kokushicilela ukufumana ukumanzisa okulungileyo ukuze intlama yombala ingene kwifiber ngokulinganayo. Amalaphu ePlastiki anje ngepolyester ngamanye amaxesha kufuneka abe nobushushu ukuze kuncitshiswe ukushwabana kunye ne-deformation ngexesha lenkqubo yokushicilela.

5. Indlela yoshicilelo

Ngokwenkqubo yokushicilela, kukho ukuprintwa ngokuthe ngqo, ukuchasana nokudaya ukuprinta kunye nokukhutshwa kokushicilela. Ngokwezixhobo zokuprinta, kukho ukuprintwa kwe-roller, isikriniushicilelokunye nokudlulisa ushicilelo, njl. Ukusuka kwindlela yoshicilelo, kukho ushicilelo olwenziwa ngesandla kunye noshicilelo ngoomatshini. Ukuprintwa koomatshini ikakhulu kubandakanya ukuprintwa kwesikrini, ukuprintwa kwe-roller, ukuprintwa kokudluliselwa kunye nokuprintwa kokutshiza, izicelo ezimbini zokuqala zixhaphake kakhulu.

6. Indlela yokushicilela kunye neempawu zayo

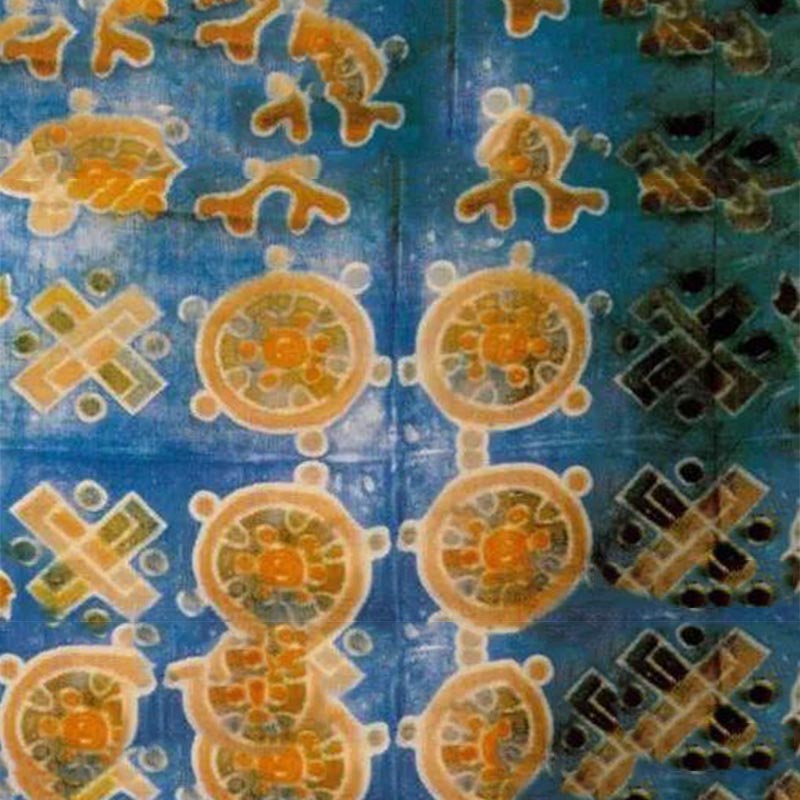

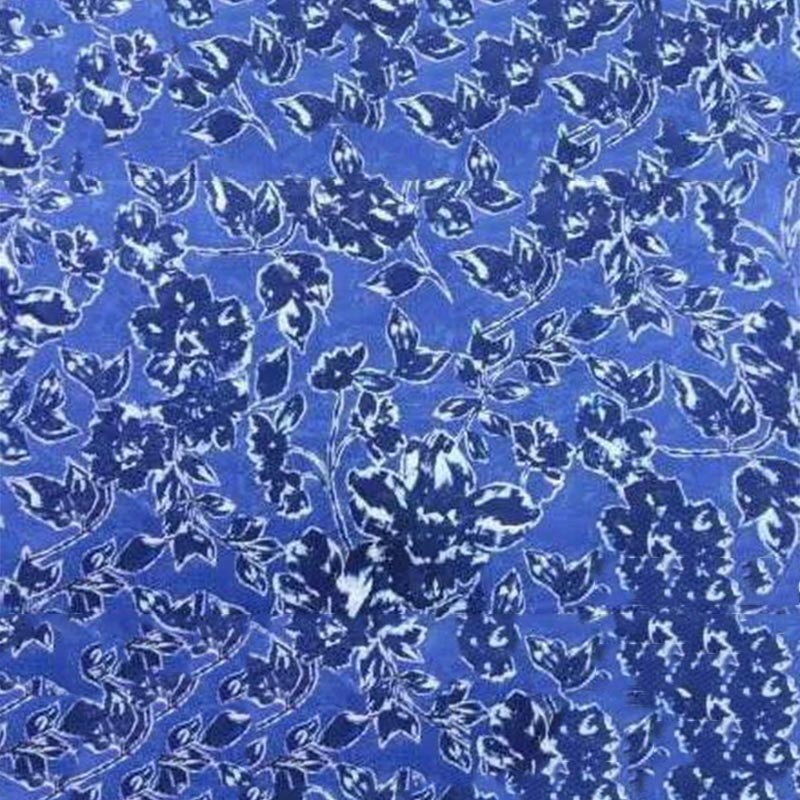

Ukuprintwa kwelaphu ngokwezixhobo zokuprinta kunokwahlulwa zibe: ukuprintwa kwesikrini, ukuprintwa kwe-roller, ukuprintwa kobushushu, ukuprintwa kwetemplate yeplanga, ukuprinta ipleyiti engenanto, i-tie-dye, i-batik, i-splash printing, ukuprinta ngesandla kunye nokunye. Kukho iindlela ezimbini zokushicilela ezibaluleke kakhulu kwintengiso: ukuprintwa kwesikrini kunye noshicilelo lwe-roller. Indlela yesithathu kushicilelo lokudlulisa ubushushu, olubaluleke kakhulu. Ezinye iindlela zoshicilelo ezingafane zisetyenziswe kwimveliso yelaphu kukushicilelwa komthi ngestencil, i-wax valerian (oko kukuthi i-Wax resistant) ushicilelo, ushicilelo lwentambo yokubopha idayi kunye noshicilelo oluxhathisayo. Uninzi lwezityalo zokuprinta i-textile zisebenzisa ukuprintwa kwesikrini kunye ne-roller yokushicilela ukuprinta amalaphu. Uninzi loshicilelo lokuhambisa ubushushu olwenziwa zizityalo zokuprinta nalo luprintwa ngale ndlela.

7. Iindlela zokushicilela zemveli

(1) Wood template yoshicilelo: Indlela yeushicilelokwilaphu kwiplanga eliphakanyisiweyo.

(2) umngxuma-uhlobo loshicilelo: Ikakhulu yahlulahlulwe yaziindidi ezithathu: umngxuma-uhlobo intlama emhlophe anti-dayi indigo yoshicilelo, umngxuma-uhlobo intlama emhlophe anti-idayi yoshicilelo kunye nohlobo umngxuma-uhlobo yoshicilelo ngqo ushicilelo.

3

4

5 Isetyenziswa rhoqo kwisilika.

6

8. Ukuprintwa kwesikrini

Ukuprintwa kwesikrini kubandakanya ukulungiswa kwesikrini sokushicilela, isikrini sokushicilela (Isikrini esisetyenzisiweyo kwinkqubo yoshicilelo sasikhe senziwe ngesilika ebhityileyo, inkqubo ebizwa ngokuba yi-screen printing yenziwe ngenayiloni, i-polyester okanye ilaphu locingo kunye ne-mesh ecikizekileyo eyolulwe phezu kwesakhelo somthi okanye sentsimbi. Ilaphu lesikrini lifakwe ifilimu e-opaque, engekho-porous. Apho kukho i-paquesh ye-paquesh kunye ne-plate yefilimu kufuneka isuswe, ifilimu ecocekileyo kufuneka isuswe. yinxalenye apho ipateni iza kuprintwa. Uninzi lwamalaphu esikrini sorhwebo aqatywa ngefilimu ethatha ifoto, kwaye emva koko ifilimu isuswa ngendlela yokuthatha iifoto ukuze iveze ipateni ukuze iprintelwe isikrini esahlukileyo, injongo yokushicilela umbala owahlukileyo.

9. Ukuprintwa kwesikrini ngesandla

Ukuprintwa kwesikrini sesandla kuveliswa ngokurhweba kwiitafile ezinde (ukuya kuthi ga kwiiyadi ezingama-60). Umqulu oshicilelweyo wendwangu usasazwa kakuhle etafileni, kwaye ubuso betafile bufakwe ngaphambili kunye nenani elincinci lezinto ezinamathele. Umshicileli ke ngokuqhubekayo uhambisa isakhelo ecaleni kwetafile yonke, eprinta isakhelo esinye ngexesha, de ilaphu liprintwe ngokupheleleyo. Isakhelo ngasinye sihambelana nepateni eprintiweyo. Izinga lemveliso yale ndlela yi-50-90 yeeyadi ngeyure. Ushicilelo lwesikrini sesandla sorhwebo lukwasetyenziswa ngobuninzi ukuprinta iziqwenga ezisikiweyo. Kwiilaphuinkqubo yoshicilelo, inkqubo yokwenza iimpahla kunye nenkqubo yokushicilela zilungelelaniswe kunye.

Uyilo oluqhelekileyo okanye olulodwa luprintwa kwiziqwenga ngaphambi kokuba zithungwe kunye. Ngenxa yokuba ukuprintwa kwesikrini ngesandla kunokuvelisa iifreyimu ezinkulu zemesh zeepateni ezinkulu, amalaphu anje ngetawuli zaselwandle, iifaskoti eziprintiweyo ezintsha, iikhethini kunye neekhethini zeshawa zinokuprintwa ngale ndlela yokushicilela. Ukuprintwa kwesikrini sesandla kukwasetyenziselwa ukuprinta inani eliqingqiweyo lempahla yabasetyhini esefashonini ephezulu kunye nokuprinta iibhetshi ezincinci zeemveliso zovavanyo lwentengiso.

(1) Ukuprintwa kwesikrini ngokuzenzekelayo

Ukuprintwa kwesikrini ngokuzenzekelayo (okanye ukuprintwa kwesikrini esicaba) kuyafana nesikrini semanuwali ngaphandle kokuba inkqubo izenzekelayo, ngoko ikhawuleza. Ilaphu eliprintiweyo lihanjiswa ngebhendi yerabha ebanzi kwiscreen, kunokuba ibekwe kwitafile ende (njengoko kunjalo ngokuprintwa kwesikrini ngesandla). Njengoshicilelo lwesikrini esizenzekelayo, ushicilelo lwekhusi oluzenzekelayo luyinkqubo engapheliyo kunenkqubo eqhubekayo.

Kule nkqubo, ilaphu lihamba phantsi kwesikrini, lize liyeke, kwaye isikrini sikrwelwa yi-scraper (i-automatic scraping), emva koko ilaphu liqhubeka lihamba phantsi kwesakhelo esilandelayo, ngesantya sokuvelisa malunga neeyadi ezingama-500 ngeyure. Ukuprintwa kwesikrini okuzenzekelayo kungasetyenziselwa kuphela umqulu wonke welaphu, iziqwenga ezisikiweyo azishicilelwanga ngale ndlela. Njengenkqubo yemveliso yorhwebo, ngenxa yokukhetha ukuprintwa kwesikrini sesetyhula kunye nokusebenza okuphezulu kwemveliso, ukuveliswa kokuprintwa kwesikrini ngokuzenzekelayo (kubhekiselele kushicilelo lwesikrini esicaba) siyancipha.

(2) Ukuprintwa kwesikrini seRotary

Ushicilelo olujikelezayo lwesikrini luyohluka kwezinye iindlela zoshicilelo lwesikrini ngeendlela ezininzi ezibalulekileyo. Ukuprintwa kwesikrini se-Rotary, njengokuprintwa kwe-roller echazwe kwicandelo elilandelayo, yinkqubo eqhubekayo apho i-cloth eprintiweyo ithuthwa nge-rubber band ebanzi phantsi kwe-cylinder ehambayo. Kushicilelo lwesikrini, isantya sokuvelisa sokuprintwa kwesikrini sesetyhula yeyona ikhawulezayo, inkulu kuneeyadi ezingama-3,500 ngeyure. Sebenzisa umnatha wesinyithi onomthungo ongenamthungo okanye umnatha weplastiki. Esona sangqa sikhulu sikhulu kune-intshi ezingama-40 kwisangqa, ngoko ke ubukhulu bentyatyambo-emva bukhulu bungaphezulu kwe-intshi ezingama-40. Oomatshini bokushicilela bescreen seRotary abaneesethi zemibala ezingaphezu kwama-20 baye baveliswa, yaye le ndlela yokushicilela ngokuthe ngcembe ithabathel’ indawo i-cylinder printing.

(3) Ukuprintwa kweerola

Ngokufana nokuprintwa kwephephandaba, ukuprintwa kwe-roller yinkqubo enesantya esiphezulu enokuvelisa ngaphezu kweemitha ezingama-6,000 zelaphu eliprintiweyo ngeyure. Le ndlela ikwabizwa ngokuba ngumatshini wokushicilela. Ekushicileleni i-roller, ipateni iprintwa kwindwangu nge-drum yethusi eqoshiwe (okanye i-roller). Igubu lobhedu liyakwazi ukukrolwa ngokusondeleyo ngokucwangcisiweyo imigca emihle kakhulu, ngoko inokushicilela iinkcukacha ezicacileyo, iipateni ezithambileyo. Umzekelo, ushicilelo olucolekileyo, oluxineneyo lwePelizli luhlobo lwepateni eprintwe ngokuprintwa kwe-roller.

Umkrolo we-cylinder kufuneka uhambelane ngokupheleleyo noyilo lomyili wepateni, kwaye umbala ngamnye ufuna i-roller ekroliweyo (kwishishini le-textile processing ekhethekileyo yokushicilela, ukuprintwa kwe-roller emihlanu, ukuprintwa kwe-roller ezintandathu, njl., ngokuqhelekileyo isetyenziselwa ukumela iiseti ezintlanu zemibala okanye iiseti ezintandathu zemibala yokushicilela). Ukuprintwa kweRoller yeyona ndlela incinci isetyenziswayo yemveliso yoshicilelo, kwaye imveliso iyaqhubeka nokuhla ngonyaka. Le ndlela ibingayi kuba yeyoqoqosho ukuba izixa eziveliswe kwipateni nganye bezingenkulu kakhulu.

(4) Ushicilelo lokudlulisa ubushushu

Umgaqo woshicilelo wokudlulisa ubushushu ufana noko kwindlela yoshicilelo lodluliselo. Ekushicileleni ukutshintshwa kobushushu, iphethini iqala ukuprintwa kwiphepha eliqukethe idayi ezihlakazayo kunye nee-inki zokuprinta, kwaye ke iphepha eliprintiweyo (elikwabizwa ngokuba liphepha lokudlulisa) ligcinwa ukuze lisetyenziswe kwizityalo zokuprinta i-textile. Xa ilaphu ishicilelwe, umatshini yoshicilelo transfer ubushushu yenza iphepha transfer kunye nobuso obungashicilelwanga ngobuso bunamathele kunye, kwaye udlula kumatshini malunga ne-210 ° C (400T), kubushushu obunjalo obuphezulu, idayi kwi-sublimates yephepha lokudlulisa kwaye idluliselwe kwilaphu, ukugqiba inkqubo yoshicilelo ngaphandle kokuqhubekela phambili. Inkqubo ilula kwaye ayifuni buchule obuyimfuneko kwimveliso yoshicilelo lwe-roller okanye ushicilelo olujikelezayo lwekhusi Ukusasaza idayi yidayi kuphela enokuthi i-sublimate, kwaye ngengqiqo iidayi kuphela ezinokufudumeza iintyatyambo ezifudumalayo, ngoko ke inkqubo ingasetyenziswa kuphela kumalaphu aqulunqwe ngemicu enobudlelwane bedayi ezinjalo, kubandakanya i-fiberstricate polystyrene, i-fiberstricate polycystic. (inayiloni) kunye neentsinga zepolyester.

(5) Ushicilelo lweJet

Ukuprintwa kweJet kukutshiza amaconsi amancinci edayi kwaye uhlale kwindawo echanekileyo yelaphu, umlomo kunye nokwakheka kwepateni esetyenziselwa ukutshiza idayi inokulawulwa yikhompyuter, kwaye inokufumana iipateni ezinzima kunye nemijikelo yepateni echanekileyo. Ukuprintwa kweJet kuphelisa ukulibaziseka kunye neendleko ezinxulumene nokukrola iirola kunye nokwenza izikrini, inzuzo yokukhuphisana kwimarike ye-textile eguquka ngokukhawuleza.

Inkqubo yoshicilelo yejethi iyaguquguquka kwaye iyakhawuleza, kwaye inokutshintsha ngokukhawuleza ukusuka kwipatheni enye ukuya kwenye. Amalaphu ashicilelweyo awanyanzelwanga (oko kukuthi, ipateni ayigqwethwanga ngokuzolula), kwaye umphezulu welaphu awusongwanga, ngaloo ndlela ususa iingxaki ezinokubakho ezifana nelaphu yefuzz okanye uboya begusha. Nangona kunjalo, le nkqubo ayikwazi ukuprinta iipatheni ezintle, ulwandlalo lwepatheni lufiphaziwe. Okwangoku, indlela yokushicilela i-jet iphantse isetyenziswe ukuprinta kwikhaphethi, kwaye akuyona inkqubo ebalulekileyo yokushicilela i-textile textile. Nangona kunjalo, ngophando kunye nophuhliso lwetekhnoloji yokulawula oomatshini kunye ne-elektroniki, le meko inokutshintsha.

Ixesha lokuposa: Jan-22-2025