①Indlela esisiseko yoshicilelo

Ukushicilela ngokwezixhobo zokuprinta kunokwahlulwa kushicilelo oluthe ngqo, ukukhutshwa koshicilelo kunye nokuchasana nokudaya.

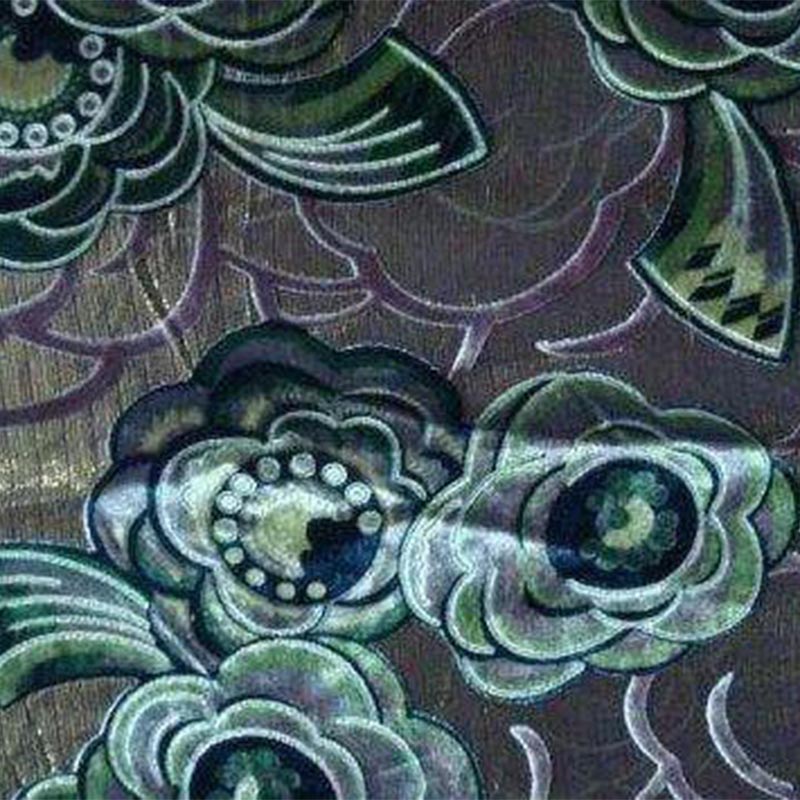

1.Ushicilelo oluthe ngqo Ushicilelo oluthe ngqo luhlobo loshicilelo ngokuthe ngqo kwilaphu elimhlophe okanye kwilaphu esele lidaywe ngaphambili. Le yokugqibela ibizwa ngokuba yi-mask print. Ngokuqinisekileyo, umbala wepateni yokushicilela umnyama kakhulu kunombala ongasemva. Inani elikhulu leendlela zokushicilela eziqhelekileyo kushicilelo oluthe ngqo. Ukuba umbala ongasemva welaphu umhlophe okanye umhlophe ubukhulu becala, kwaye ipateni yoshicilelo ibonakala ilula ukusuka ngasemva kunombala wangaphambili, ngoko sinokugqiba ukuba oku kuthe ngqo.ilaphu eliprintiweyo(Qaphela: ngenxa yokungena okunamandla kwi-paste yokushicilela, ngoko ke ilaphu elikhanyayo alinakugwetywa ngale ndlela). Ukuba umphambili nasemva kombala wemvelaphi yelaphu uyafana (kuba idayi yesiqwenga), kwaye ipateni yokuprinta imnyama kakhulu kunombala ongasemva, ke le yilaphu lokuprinta lokugquma.

2. Ukukhutshwa kokushicilela Ukuprintwa kwe-Discharge kuqhutyelwa ngamanyathelo amabini, isinyathelo sokuqala kukudaya i-monochrome yelaphu, kwaye inyathelo lesibini kukuprinta iphethini kwindwangu. I-paste yokushicilela kwisinyathelo sesibini iqulethe i-agent eqinile ye-bleaching enokuthi itshabalalise idayi yombala wesiseko, ngoko le ndlela inokuvelisa i-blue and white polka dot patterning cloth, ebizwa ngokuba yi-white extraction.

Xa i-bleach kunye nedayi engayi kusabela ngayo ixutywe kumbala ofanayo we-paste (iidayi ze-VAT zolu hlobo), ukushicilelwa kombala kunokwenziwa. Ngoko ke, xa idayi etyheli efanelekileyo (efana nedayi ye-VAT) ixutywe ne-bleach enemibala, ipateni ye-polka dot etyheli inokuprintwa kwilaphu eliluhlaza okwesibhakabhaka.

Ngenxa yokuba umbala osisiseko wokushicilela ukukhutshwa kuqala udaywe yindlela yokudaya isiqwenga, ukuba umbala wesiseko ofanayo uprintwa emhlabeni kunokuba umbala ucebile kwaye unzulu. Le yinjongo ephambili yokuprinta ukukhupha. Ukukhutshwa kweendwangu zokuprinta kunokuprintwa ngokuprintwa kwe-roller kunye nokuprintwa kwesikrini, kodwa kungekhona ngokushicilela ukushisa. Ngenxa yeendleko eziphezulu zemveliso yelaphu eliprintiweyo xa kuthelekiswa noshicilelo oluthe ngqo, ukusetyenziswa kwe-arhente yokunciphisa efunekayo kufuneka kulawulwe ngononophelo nangokuchanekileyo. Amalaphu aprintiweyo ngale ndlela anentengiso engcono kunye namaxabiso aphezulu. Ngamanye amaxesha, ii-agent zokunciphisa ezisetyenziswe kule nkqubo zingabangela umonakalo okanye ukutshatyalaliswa kwelaphu kwipatheni eprintiweyo. Ukuba umbala wamacala omabini welaphu uyafana (kuba idayi yesiqwenga), kwaye ipateni imhlophe okanye imbala eyahlukileyo ukusuka kumbala ongasemva, unokuqinisekiswa ukuba ukukhutshwa kwendwangu eprintiweyo.

3. Anti-dayi yoshicilelo Anti-dayi yoshicilelo ibandakanya izigaba ezibini:

(1) Ilaphu elimhlophe liprintwa linemichiza okanye iiresin ezinewaxy ezithintela okanye ezithintela idayi ekungeneni kwelaphu;

(2) ilaphu elidayiweyo. Injongo kukudaya umbala wesiseko ukukhupha ipateni emhlophe. Qaphela ukuba umphumo ufana nelaphu eliprintiweyo lokukhupha, nangona kunjalo indlela esetyenziselwa ukufezekisa esi siphumo ichasene nokukhupha ilaphu eliprintiweyo. Ukusetyenziswa kwendlela yokushicilela i-anti-dayi ayiqhelekanga, kwaye isetyenziswa ngokuqhelekileyo xa umbala wesiseko awukwazi ukukhutshwa. Kunokuba isiseko esikhulu sokuvelisa, ushicilelo oluninzi oluchasene nedayi lufezekiswa ngeendlela ezifana nezandla okanye ukuprintwa kwesandla (njenge-wax yokuchasana nokushicilela). Ngenxa yokuba ukuprintwa kokukhutshwa kunye nokuchasana kwedayi kuvelisa umphumo ofanayo wokuprinta, ngokuqhelekileyo akunakuhlukaniswa ngokujongwa kwamehlo.

4. Ukuprintwa kwepeyinti Ukusetyenziswa kwepeyinti kunokuba idayi ukuvelisa amalaphu aprintiweyo kuye kwasasazeka kangangokuba sele kuqaliswe ukuthathwa njengendlela yokushicilela ezimeleyo. Ukuprintwa kwepeyinti kukuprintwa ngokuthe ngqo kwepeyinti, inkqubo idla ngokubizwa ngokuba yiprinting eyomileyo, ukwenzela ukwahlula kushicilelo olumanzi (okanye ukuprinta kwedayi). Ngokuthelekisa umahluko wobulukhuni phakathi kwenxalenye eprintiweyo kunye nenxalenye engashicilelwanga kwilaphu elifanayo, ukuprintwa kwepeyinti kunye nokushicilela idayi kunokwahlulwa. Indawo eprintiweyo yepeyinti ivakalelwa kancinci kunendawo engashicilelwanga, mhlawumbi incinci. Ukuba ilaphu liprintwe ngedayi, akukho mahluko ubalulekileyo wokuqina phakathi kwenxalenye eprintiweyo kunye nenxalenye engashicilelwanga.

Iiprinta zepeyinti emnyama zinokuziva zinzima kwaye zithambile kancinci kunemibala ekhanyayo okanye elula. Xa uphonononga isiqwenga selaphu elineeprinta zepeyinti ezikhoyo, qiniseka ukuba ujonga yonke imibala, njengoko zombini idayi kunye nepeyinti zinokubakho kwilaphu elinye. Ipeyinti emhlophe nayo isetyenziselwa ukuprinta, kwaye le nto ayifanele ihoywe. Ukuprintwa kwepeyinti yindlela ephantsi yokushicilela kwimveliso yoshicilelo, kuba ukuprintwa kwepeyinti kulula, inkqubo efunekayo incinci, kwaye ngokuqhelekileyo ayifuni ukutshisa kunye nokuhlamba.

Iingubo ziza ngemibala eqaqambileyo, etyebileyo kwaye zinokusetyenziswa kuzo zonke iintsinga zelaphu. Ukukhawuleza kwabo ukukhanya kunye nokucocwa kokucoca okomileyo kulungile, nokuba kuhle kakhulu, ngoko ke basetyenziswa ngokubanzi kwiilaphu zokuhombisa, amalaphu amakhethini kunye neengubo zokugqoka ezifuna ukucocwa okomileyo. Ukongeza, ukugquma phantse akuvelisi umahluko omkhulu wemibala kwiibhetshi ezahlukeneyo zelaphu, kwaye ukugqunywa kombala wesiseko kukwalungile kakhulu xa imaski iprintwa.

Ushicilelo olukhethekileyo

Indlela esisiseko yoshicilelo (njengoko kukhankanyiwe ngasentla) kukuprinta ipateni kwilaphu, umbala ngamnye kwipatheni esetyenziswe kwindlela yokushicilela kunye nokudaya, ukushicilela okukhethekileyo kuluhlu lwesibini, isizathu solu luhlu, kuba le ndlela inokufumana umphumo okhethekileyo wokushicilela, okanye ngenxa yokuba iindleko zenkqubo ziphezulu kwaye azisetyenziswanga ngokubanzi.

1. Ukuprintwa komgangatho Umbala wesiseko soshicilelo ufunyanwa ngendlela yokushicilela kunokusebenzisa indlela yokudaya isiqwenga. Ngokuqhelekileyo kwinkqubo yokushicilela, zombini umbala wesiseko kunye nombala wepatheni ziprintwa kwengubo emhlophe. Ngamanye amaxesha ukuprintwa komgangatho ogcweleyo kulungiselelwe ukulinganisa umphumo wokukhutshwa okanye ukuchasana kwedayi ebiza kakhulu ukuvelisa, kodwa kulula ukuhlukanisa iiprinta ezahlukeneyo ukusuka ngasemva kwengubo. Icala elingasemva lokuprinta komhlaba lilula; Ngenxa yokuba ilaphu lidaywe kuqala, macala omabini okukhutshwa okanye ukuprintwa kwedayi anombala ofanayo.

Ingxaki ngokuprintwa komgangatho ogcweleyo kukuba ngamanye amaxesha iindawo ezinkulu zombala ongasemva azinakugqunywa ngemibala emnyama. Xa le ngxaki isenzeka, jonga ngononophelo ipateni emhlabeni, uya kufumana amabala amnyama. Le nto ibangelwa ngokusisiseko ngokuhlamba, kungekhona ngenxa yobuninzi bokugquma idayi.

Ezi ziganeko azenzeki kwiingubo eziphakamileyo eziprintiweyo eziveliswe phantsi kweemeko ezingqongqo zobuchwepheshe. Le nto ayinakwenzeka xa indlela yoshicilelo lwesikrini isetyenziselwa ukuprinta kuwo wonke umgangatho, kuba intlama yombala ikhutshiwe, kunokuba ifakwe njenge-roller yokushicilela. Amalaphu aprintiweyo agqunywe phantsi adla ngokuziva eqinile.

2. Ushicilelo lokupakisha Ushicilelo lwe-flocking yindlela yoshicilelo apho imfumba yefiber ebizwa ngokuba yi-fiber short pile (malunga ne-1/10-1/4 intshi) ibambelele kumphezulu welaphu kwipatheni ethile. Inkqubo yamanqanaba amabini iqala ngokuprinta ipateni kwilaphu kunye ne-adhesive endaweni yedayi okanye ipeyinti, ize idibanise ilaphu kunye ne-fiber stub, ehlala kwindawo kuphela apho i-adhesive ifakwe khona. Kukho iindlela ezimbini zokuncamathisela ukuthontelana okufutshane kumphezulu welaphu: ukubutha ngoomatshini kunye nokuhlangana kwe-electrostatic. Xa kuthungelana ngoomatshini, iintsinga ezimfutshane zihluzwa elaphuni njengoko lidlula kwigumbi lokufuduka kububanzi obusicaba.

Xa ushukunyiswa ngumatshini, ilaphu liyangcangcazela, kwaye imicu emifutshane ifakwe ngokungacwangciswanga kwilaphu. Kwimisinga ye-electrostatic, umbane ongashukumiyo usetyenziswa kwiintsinga ezimfutshane, nto leyo ekhokelela ekujongeni ngokuthe tye kwayo yonke imicu xa incamatheliswe elaphu. Xa kuthelekiswa nokuthontelana ngoomatshini, ukuhamba nge-electrostatic kuyacotha kwaye kuyabiza, kodwa kunokuvelisa isiphumo esifanayo kunye nesixineneyo sokuthontelana. Iintsinga ezisetyenziswa kwi-electrostatic flocking ziquka zonke iintsinga ezisetyenziswa kwimveliso yokwenyani, apho imicu ye-viscose kunye nenayiloni zezona zixhaphakileyo.

Kwiimeko ezininzi, iifayibha ezisisiseko zidaywe ngaphambi kokuba zitshintshwe kwilaphu. Ikhono lelaphu lokuhlalisa ukumelana nokucoca okomileyo kunye / okanye ukuhlamba kuxhomekeke kubume be-adhesive. Izinto ezininzi zokuncamathelisa ezikumgangatho ophezulu ezisetyenziswa ekulungiseni ilaphu zinokukhawuleza okubalaseleyo ekuhlambeni, ekucoceni okomileyo, okanye zombini. Ngenxa yokuba ayizizo zonke izinto zokuncamathelisa ezinokumelana naluphi na uhlobo lokucoca, kuyafuneka ukuba kuqinisekiswe ukuba yeyiphi indlela yokucoca ilungele naliphi na ilaphu elithile lokuthontelana.

3.Warp yoshicilelo Warp yoshicilelo kuthetha ukuba phambi kokuluka, i-warp yelaphu iprintwe kwaye emva koko ilukwe kunye ne-weft ecacileyo (ngokuqhelekileyo emhlophe) ukudala ilaphu, kodwa ngamanye amaxesha umbala we-weft wahluke kakhulu kumbala we-warp eprintiweyo. Isiphumo sisithunzi-ziinkozo ezithambileyo, kunye nempembelelo yepateni emfiliba kwilaphu. Ukuveliswa koshicilelo lwe-warp kufuna ukunakekelwa kunye neenkcukacha, ngoko ke phantse kufumaneka kuphela kwiingubo eziphezulu, kodwa iingubo ezenziwe ngeentambo ezinokuprintwa ngokugqithiswa kobushushu zihlukile. Ngophuhliso loshicilelo lokuhanjiswa kobushushu be-warp, iindleko zoshicilelo lwe-warp ziye zancitshiswa kakhulu. Ukuprintwa kwe-Warp kunokuchongwa ngokukhupha i-warp kunye ne-weft yelaphu, kuba kuphela i-warp inombala wepatheni, kwaye i-weft imhlophe okanye ilula. Ukulinganisa i-warp iziphumo zoshicilelo nazo zinokuprintwa, kodwa oku kulula ukuchongwa kuba umbala wepatheni ukhona kuzo zombini i-warp kunye ne-weft.

4.kutshiswe printing

Ukubola koshicilelo kukushicilelwa kweekhemikhali ezinokonakalisa izicubu zefiber kwipateni. Ngenxa yoko, kukho imingxuma apho imichiza idibana nelaphu. I-Mitation mesh embroidery ilaphu inokufumaneka ngokuprinta nge-2 okanye i-3 rollers, enye i-roller iqulethe iikhemikhali ezitshabalalisayo, kunye nezinye ii-roller ziprinta i-stitch ye-embroidery yokuxelisa.

La malaphu asetyenziselwa iibhlawuzi zasehlotyeni ezinexabiso eliphantsi kunye nemiphetho ekrwada yempahla yangaphantsi yomqhaphu. Imiphetho yemingxuma kwiiprinta ezigugileyo zihlala ziphantsi konxitywa kwangaphambi kwexesha, ngoko ke ilaphu lihlala lihleli. Olunye uhlobo loshicilelo lweentyatyambo ngamalaphu enziwe ngomsonto odityanisiweyo, umsonto ocandiweyo, okanye umxube wemicu emibini okanye ngaphezulu, apho imichiza inokutshabalalisa ifayibha enye (i-cellulose), ishiye enye ingonakaliswa. Le ndlela yokushicilela inokushicilela amalaphu amaninzi akhethekileyo kunye anomdla ashicilelweyo.

Ilaphu lingenziwa nge-viscose / i-polyester 50/50 edityanisiweyo yomsonto, kwaye xa kushicilelwa, inxalenye yefayibha ye-viscose iyanyamalala (ibolile), ishiya i-polyester ifayibha engonakaliswanga, okukhokelela ekushicileleni kwe-polyester kuphela, kunye ne-polyester engashicilelwanga / i-viscose ifayibha edibeneyo isampuli yoqobo.

5.Ushicilelo olunamacala amabini

Amacala amabiniushicileloishicilela kumacala omabini elaphu ukufumana isiphumo esinamacala amabini elaphu, elifana nenkangeleko yamalaphu okupakisha aprintwe ngepateni elungelelanisiweyo macala omabini. Ukusetyenziswa kokugqibela kunqunyelwe kumaphepha aphindwe kabini, iingubo zeetafile, iibhatyi ezingenanto okanye ezimbini kunye neekhati.

6. Iiprinta ezikhethekileyo Iiprinta ezikhethekileyo ziprinta ngeepatheni ezimbini okanye ezingaphezulu, nganye iprintwe kwindawo eyahlukileyo yengubo, ngoko ke iphethini nganye iya kuba kwindawo ethile kwisambatho. Umzekelo, umyili wefashoni uza kuyila iblowusi enamachokoza epolka aluhlaza namhlophe ngaphambili nangasemva, enemikhono efanayo eluhlaza okwesibhakabhaka namhlophe, kodwa enemigca. Kule meko, umyili wempahla usebenza kunye nomyili welaphu ukwenza zombini ichaphaza le-polka kunye nezinto zomgca kumqulu ofanayo. Ubume bendawo yokushicilela kunye nenani leeyadi zelaphu ezifunekayo kwipateni nganye yesiqalelo kufuneka zicwangciswe ngononophelo ukwenzela ukuba izinga lokusetyenziswa kwelaphu libe lelona liphezulu kwaye lingabangi inkunkuma eninzi kakhulu. Olunye uhlobo lokuprinta olukhethekileyo luprintwa kwiimpahla ezisele zisikiwe, njengeengxowa kunye neekhola, ukwenzela ukuba iipatheni ezininzi ezahlukeneyo kunye nezahlukileyo zempahla zingadalwa. Amaphepha angaprintwa ngesandla okanye ngokugqithiswa kobushushu.

Inkqubo yoshicilelo yendabuko ibandakanya ukuyila ipateni, i-cylinder engraving (okanye ukwenza ipleyiti yesikrini, ukuveliswa kwesikrini esijikelezileyo), ukumodareyitha kombala we-paste kunye nephethini eprintiweyo, i-post-treatment (i-steaming, i-desizing, i-washing) kunye nezinye iinkqubo ezine.

②uyilo lwepateni

1.Ngokokusetyenziswa kwelaphu (elifana nelamadoda,Abafazi, amaqhina, izikhafu, njalo njalo) bamba isimbo, ithoni kunye nepateni yepateni.

2. Ngokuhambelana nesimbo semathiriyeli yelaphu, njengesilika kunye neemveliso zehemp ezigqwesileyo kunye nokucoceka kombala kunomahluko omkhulu kakhulu.

3. Ubuchule bokubonakaliswa kwepateni, ukwakheka kombala kunye nepateni kufuneka kuhambelane nenkqubo yokushicilela kunye nobubanzi bendwangu, ulwalathiso lwentambo, ukusika kunye nokuthunga kwempahla kunye nezinye izinto. Ngokukodwa iindlela ezahlukeneyo zokushicilela, isitayela sepateni kunye nobuchule bokusebenza nazo zihluke, njengenani leesethi zemibala yokushicilela i-roller yi-1 ukuya kwi-6 iisethi, kwaye ububanzi beentyatyambo bukhawulelwe ngobukhulu be-roller; Inani leeseti zemibala yoshicilelo lwesikrini linokufikelela kwiiseti ezingaphezu kwe-10, kwaye umjikelo wolungelelwaniso unokuba mkhulu ngokwaneleyo ukuprinta ilaphu elinye, kodwa alifanelekanga kuyilo lweepateni zejometri ezicocekileyo neziqhelekileyo.

4. Uyilo lwesitayile sepateni kufuneka luthathele ingqalelo inzuzo yentengiso kunye nezoqoqosho

③Ukukrolwa kwesilinda seentyatyambo, ukwenziwa kwepleyiti yesikrini, ukwenza umnatha ongqukuva

I-cylinder, isikrini kunye nesikrini esijikelezayo zixhobo ezithile zenkqubo yokushicilela. Ukuze wenze ipateni eyiliweyo ivelise ipateni ehambelanayo kwilaphu phantsi kwesenzo sokuncamathisela kombala, kuyimfuneko ukuphumeza inkqubo yobunjineli efana nokukrolwa kwe-cylinder, ukwenza ipleyiti yesikrini kunye nokwenziwa kwesetyhula, ukwenzela ukuba kuqulunqwe imodeli ehambelanayo yomzekelo.

1. I-cylinder engraving: ukuprintwa komatshini wokushicilela i-cylinder, i-pattern engraving kwi-cylinder yethusi, kukho imigca ye-twill okanye amachaphaza, asetyenziselwa ukugcina umbala wombala. Inkqubo yokukrola iipateni ze-concave kumphezulu we-roller yobhedu ibizwa ngokuba yi-cylinder engraving. I-cylinder yenziwe ngentsimbi egobileyo yobhedu ehlanganiswe okanye iphoswe ngobhedu, i-circumference ngokuqhelekileyo yi-400 ~ 500mm, ubude buxhomekeke kwi-amplitude yomatshini wokushicilela. Iindlela zokukrola iipateni ziquka ukukrolwa kwesandla, ukukrolwa kombindi wobhedu, ukukrola okuncinci, ukukrolwa kweefoto, ukukrolwa kwe-elektroniki njalo njalo.

2. Ukwenza ipleyiti yesikrini: ukuprintwa kwesikrini esicaba kufuneka kwenziwe isikrini esihambelanayo. Ukwenza ipleyiti yesikrini esisicaba kubandakanya ukwenziwa kwesakhelo sesikrini, ukwenza umnatha kunye nokwenza ipateni yesikrini. Isakhelo sesikrini senziwe ngomthi oqinileyo okanye imathiriyeli ye-aluminiyam, kwaye emva koko ingcaciso ethile yenayiloni, ipolyester okanye ilaphu lesilika yoluliwe kwisakhelo sesikrini, oko kukuthi, isikrini. Ukuveliswa kweepateni zesikrini ngokuqhelekileyo kusetyenziswa indlela ye-photosensitive (okanye indlela yokwahlula umbala we-elektroniki) okanye indlela yokuchasana nepeyinti.

3. Round net production: Ushicilelo olujikelezileyo kufuneka lwenziwe. Umnatha we-nickel onemingxuma uqala ukwenziwa, kwaye emva koko isakhelo sesinyithi esingqukuva sisetwa kuzo zombini iziphelo zenethi ye-nickel ukuqinisa umnatha we-nickel. Emva koko umnatha we-nickel ugqunywe ngeglue ye-photosensitive, ipateni yesampulu yokwahlukana kombala isongelwe ngokuqinileyo kumnatha we-nickel, kwaye umnatha ojikelezayo kunye nomzekelo wenziwa ngendlela ye-photosensitive.

4.Ukumodareyitha kwencama yombala kunye nepateni eprintiweyo IV. Emva konyango (ukuphunga, ukutshisa, ukuhlamba)

Emva kokuprinta kunye nokomisa, ngokuqhelekileyo kuyimfuneko ukwenza ukuqhuma, ukuphuhliswa kombala okanye unyango oluqinileyo lombala, kwaye emva koko uqhube i-desizing kunye nokuhlamba ukususa ngokupheleleyo i-paste, ii-agent zeekhemikhali kunye nombala odadayo kumbala wombala.

Ukuphunga kukwabizwa ngokuba kukuphunga. Emva kokuba i-paste yokushicilela isomile kwilaphu, ukwenzela ukuba udlulise idayi kwi-paste ukuya kwi-fiber kwaye ugcwalise utshintsho oluthile lweekhemikhali, ngokuqhelekileyo kuyimfuneko ukutshisa. Kwinkqubo yokuqhuma, umphunga uqala ukujiya kwilaphu, ubushushu belaphu bukhuphuka, i-fiber kunye ne-paste idumba, idayi kunye neekhemikhali ze-agent ziyanyibilika, kwaye ezinye iintshukumo zeekhemikhali ziyenzeka, ngeli xesha idayi igqithiselwa kwi-paste ukuya kwifayibha, ngaloo ndlela igqibezela inkqubo yokudaya.

Ukongezelela, ngenxa yobukho be-paste, inkqubo yokudaya yokuprinta idayi inzima ngakumbi, kwaye ixesha lokuphuma komphunga lide kunelo lokudaya kwepadi. Iimeko zokuphunga nazo ziyahluka kunye neempawu zedayi kunye namalaphu.

Okokugqibela, ilaphu eliprintiweyo kufuneka lenziwe lidekwe ngokupheleleyo kwaye lihlanjwe ukuze kususwe intlama, iirejenti zeekhemikhali kunye nombala odadayo kwilaphu. Intlama ihlala phezu kwelaphu, iyenza ibe rhabaxa. Umbala odadayo uhlala kwilaphu, eliya kuchaphazela ukugqama kombala kunye nokukhawuleza kokudaya.

Isiphene kwilaphu eliprintiweyo

Iziphene zoshicilelo eziqhelekileyo ezibangelwa yinkqubo yoshicilelo zidweliswe kwaye zichazwe ngezantsi. Ezi ziphene zinokubangelwa kukuphathwa ngendlela engafanelekanga kwinkqubo yokushicilela, ukuphathwa ngokungafanelekanga kwelaphu ngaphambi kokushicilela, okanye iziphene kwizinto eziprintiweyo ngokwazo. Ngenxa yokuba ukuprintwa kwelaphu kufana nokudaya ngeendlela ezininzi, uninzi lweziphene ezenzeka ekudayeni zikwakho kumalaphu ashicilelweyo.

1.Ushicilelo lokutsala ukushicilela ukucola ibala ngenxa yokukhuhlana ngaphambi kokoma.

2.Umbala wokushicilela incamathelo etshiza phantsi kwilaphu ayigudi, kodwa ichithelwe phezu okanye itshizwe kwilaphu, indawo yombala okanye umbala otshizayo.

3.Ipateni ye-fuzzy edge ayilungile, umgca awucaci, ngokuphindaphindiweyo ubangelwa ukucula okungafanelekanga okanye ukugxilwa kwe-paste akufanelekanga.

4. Iintyatyambo azivumelekanga ukuba zibe ngenxa yerola yokuprinta okanye isikrini esilungelelaniswe ngokuthe nkqo, ipateni yesizathu ngaphambi nasemva kobhaliso aluchanekanga. Esi siphene sikwabizwa ngokungafaniyo okanye ukutshintsha ipateni.

5.Yeka ukuprinta ngenxa yomatshini wokushicilela kwinkqubo yoshicilelo wayeka ngokukhawuleza, kwaye emva koko utshintshe, iziphumo eziveliswe kumbala welaphu.

6. Ingxenye ye-embrittlement kwi-cloth eprintiweyo, eprintwe ngendawo enye okanye ngaphezulu yombala idla ngokuwonakaliswa, ngokuqhelekileyo ngenxa yeekhemikhali ezinobungozi ezisetyenziselwa ukuprinta ukunamathisela. Le ngxaki inokufumaneka kwakhona kwinxalenye yomzobo yokukhutshwa kwendwangu eprintiweyo.

Ixesha lokuposa: Mar-11-2025