Ukukhethwa kokudaya kunye nenkqubo yokugqiba kusekelwe ngokukodwa kwiindidi, iinkcukacha kunye neemfuno ezigqityiweyo zemveliso yelaphu, elinokwahlulwa libe ngunyango lwangaphambili,idaying, ukuprinta, ukugqiba ukugqiba njalo njalo.

Unyango lwangaphambili

Imicu yendalo iqulethe ukungcola, kwinkqubo yokucubungula i-textile kwaye yongeza i-slurry, i-oyile kunye nokungcola okungcolileyo, ubukho bobu kungcola, kungekhona nje ukuthintela inkqubela phambili yokudaya kunye nokugqiba ukugqiba, kodwa kuchaphazela nokusebenza kwengubo.

Injongo yonyango lwangaphambili kukusebenzisa isenzo sekhemikhali kunye noomatshini bomzimba ukususa ukungcola kwilaphu, ukwenza ilaphu libe mhlophe, lithambile, kwaye libe nokungena kakuhle ukuhlangabezana neemfuno zokuthatha, kunye nokubonelela ngeemveliso eziziisiqingatha ezifanelekileyo zokudaya, ukuprinta nokugqiba.

Umqhaphu: ukulungiswa kwelaphu elikrwada, ukucula, ukudambisa, ukubilisa, ukwenza ibleaching, mercerizing. I-Polyester: ukulungiswa kwelaphu, ukucocwa (i-alkali yolwelo, njl. njl.), ukucuthwa kwangaphambili, ukugcinwa, ukuchithwa kwe-alkali (i-alkali yolwelo, njl. njl.).

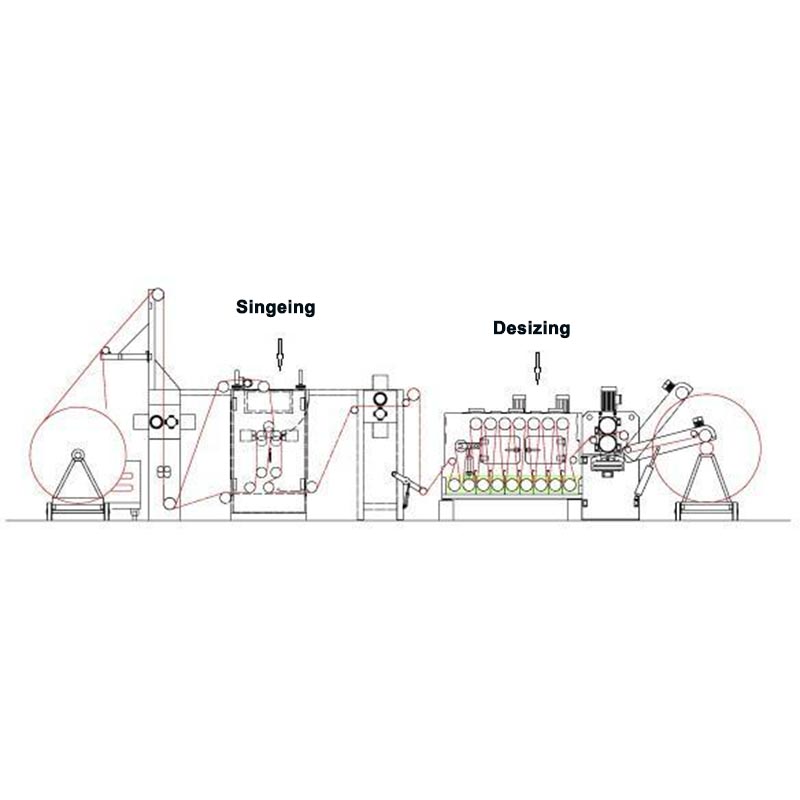

Ukucula

Ngokuqhelekileyo, emva kokungena kumzi-mveliso wokushicilela kunye nokudaya ukusuka kwi-textile mill, i-cloth engwevu kufuneka ihlolwe kuqala, iguqulwe, idibanise, iprinte kunye nokuthunga, kwaye iculwe.

Izizathu:

(1) elaphini lingatshoni phantsi kakhulu, ubude obahlukeneyo;

(2) iqondo lokugqibezela limbi, ungcoliseko olulula;

(3) ngokulandelelana zhongyi uboya ukudaya kunye nokugqiba, ushicilelo kunye nokudaya iziphene.

Injongo yokucula:

(1) ukuphucula ukubengezela kwelaphu; Phucula ukugqiba;

(2) ukuphucula ukuxhathisa iipilisi (ingakumbi ilaphu lefiber yekhemikhali);

(3) ukuphucula isitayile, ukucula kunokwenza ilaphu libe crisp, babe ngamathambo.

Ukunciphisa

Kwinkqubo yokuluka, i-warp iphantsi koxinzelelo kunye nokukhuhlana, ekulula ukuqhawula. Ukuze kuncitshiswe ukuqhawuka kwe-warp, ukuphucula ukusebenza kakuhle kokuluka kunye nomgangatho welaphu elingwevu, kuyafuneka ukuba wenze ubungakanani bomsonto phambi kokuluka. Ifiber esemsonto incamathela kwaye ibambene, kwaye yenze ifilimu eludaka oluqinileyo kumphezulu womsonto, yenza umsonto uqine kwaye ugude, ngaloo ndlela uphucula ukomelela kokuqhawuka kunye nokunxiba ukuxhathisa komsonto.

Injongo ye-Desizing: Emva kokulinganisa, i-slurry ingena kwimicu kwaye ngokuyinxenye inamathele kumphezulu we-warp. Ngelixa uphucula ukusebenza komsonto, i-slurry ingcolisa ukudaya kunye nokugqiba ulwelo lokucoca, ithintela ukusebenzisana kweekhemikhali phakathi kweefibers kunye nokudaya kunye nezixhobo zeekhemikhali, kwaye yenza kube nzima ukwenza ukudaya kunye nokugqiba ukusetyenzwa.

(1) Intshayelelo kwi-slurry esetyenziswa ngokuqhelekileyo

I-slurry yendalo: isitashi, i-seaweed gum, i-gum, njl.

Iimpawu zesitatshi:

① kwimeko yokubola kweasidi;

② kwimeko yokuzinza kwealkali, ukudumba;

③ kwimeko yee-oxidants zinokubola;

④ ngokubola kwe-enzyme yokubola kwesitatshi.

I-Chemical slurry: i-cellulose derivatives efana ne-hydroxymethylcellulose (CMC), i-polyvinyl alcohol (PVA), i-polyacrylic acid, i-polyester, njl.

Iimpawu zePVA:

① uzinzile kwi-asidi kunye nesiseko, i-viscosity ayinciphisi;

② Wonakaliswa yi-oxidant.;

③ Ukusebenza okubanzi, ukuhambelana okuhle, akukho mpendulo yokuxuba

(2) Iindlela ezixhaphakileyo ezisetyenziswayo

1. Ukwenziwa kwealkaline

Enye yeendlela ezisetyenziswa kakhulu kwizityalo zokudaya zasekhaya, kodwa izinga le-desizing aliphezulu, kwaye ezinye izinto ezingcolileyo zingasuswa ngelixa zifuna.

I-Mechanism: Ukusetyenziswa kwe-sodium hydroxide dilute unyango lwesisombululo, i-starch slurry phantsi kwesenzo sokudumba kwe-alkali (okanye ukudumba) isiganeko, akwenzeki ukusabela kweekhemikhali, ukwenzela ukuba i-slurry esuka kwi-gel ukuya kwi-sol, inciphise amandla okubopha phakathi kwe-fiber kunye ne-slurry, kwaye emva koko ukusetyenziswa kokuhlamba kunye namandla omatshini ukuyisusa. Kwi-PVA kunye ne-polyacrylate slurries, iyakwazi ukunyibilikisa i-sodium hydroxide kwizisombululo ze-dilute.

(isitatshi) i-enzyme deizing

Ii-enzyme zikwabizwa ngokuba yi-enzymes, i-biocatalysts.

Iimpawu: izinga eliphezulu le-desizing, kungekhona i-fiber yokulimala, kuphela isitashi, ayikwazi ukususa ukungcola.

Iimpawu: a. Ukusebenza okuphezulu. b. Ukucaciswa: I-enzyme inokubangela ukusabela enye kuphela okanye ukusabela okuthile. c. Umsebenzi uchatshazelwa bubushushu kunye nexabiso le-PH.

Kwi-starch slurries okanye i-slurries edibeneyo ye-starch (umxholo we-starch unamandla), i-amylase ingasetyenziselwa ukwenza i-desizing.

Ukunciphisa i-Acid

Ukusetyenziswa kwasekhaya akuninzi, kuba ukusetyenziswa kulula ukulimaza i-fiber, ngakumbi kudibaniswa nezinye iindlela. Indlela enamanyathelo amabini yamkelwe: i-alkali desizing - i-asidi desizing. I-Acid desizing inokwenza isitashi sibe yi-hydrolyze, ukususa ityuwa yeminerali kunye nokunye, kwaye wenze enye kwenye.

Ukunciphisa i-oxidation

I-agent ye-oxidizing: NaBrO2 (i-sodium bromite) H2O2, Na2S2O8, (NH4) 2S2O8, njl.

Umgaqo: I-agent e-oxidizing iyakwazi ukudibanisa kunye nokunciphisa zonke iintlobo ze-slurry, ubunzima bayo be-molecular kunye ne-viscosity iyancitshiswa kakhulu, ukunyibilika kwamanzi kwanda, kwaye i-slurry ithintelwe ukuba ibambelele kwi-fiber, kwaye ke i-hydrolyzate isuswe ngokuhlamba ngokufanelekileyo.

(1) Ukubilisa

Injongo yokubilisa kukususa ukungcola kwefayibha kunye nokuphucula iipropathi zokucutshungulwa kwelaphu, ngakumbi ukumanzisa.

Ukungcola kwendalo: Kulaphu lomqhaphu olusulungekileyo, ikakhulu izinto eziphilayo ezidibeneyo zefayibha okanye izinto ezinxulumene nazo, kubandakanya i-oyile, i-pectin, iprotein, uthuthu, i-pigment kunye namaqokobhe e-cottonseed.

Ukungcola okwenziweyo: ukungcola okufana ne-oyile, i-agent ye-antistatic kunye ne-oyile, irusi kunye nodaka olushiyekileyo olufakwe kwi-spinning kunye nokulungiswa kokuluka.

Oku kungcola kuchaphazela kakhulu ukumanzi kwelaphu kwaye kuthintele ukudaywa kunye nokugqiba kwelaphu, kwaye kufuneka kususwe kwinkqubo yokukhuhla kunye ne-sodium hydroxide njengeyona nto iphambili kunye ne-surfactants njenge-axiliary.

(2) Ukucoca

Emva kokubilisa, uninzi lokungcola kwendalo kunye nelokwenziwa kwiilaphuziyasuswa, kodwa kumalaphu afakwe iblitshi nanemibala ekhaphukhaphu, kufuneka kwenziwe ibleaching. Oko kukususa i-pigment, ukuphucula ubumhlophe njengeyona njongo iphambili yokulungisa i-bleaching.

Ifayibha yekhemikhali ayinabala labala, emva kokuba ukubilisa kube mhlophe kakhulu, kwaye ifayibha yomqhaphu emva kokukhuhla ibala lebala isekhona, ubumhlophe abulunganga, ngoko ke ukwenza ibleaching kukwenzela ubumdaka bendalo kwifiber yomqhaphu.

(3) Iblitshi

Uhlobo lwe-oxidation: i-hypochlorite ye-sodium, i-hydrogen peroxide kunye ne-sodium chlorite, njl., isetyenziswa kakhulu kwi-cotton fiber kunye nempahla edibeneyo.

Ukunciphisa: I-NaHSO3 kunye nomgubo we-inshurensi, njl., ikakhulu isetyenziselwa iiprotheyini zefiber fabrics.

(4) Isodium hypochlorite bleaching:

Isodium hypochlorite bleaching isetyenziswa ikakhulu ukwenza ilaphu yomqhaphu emhlophe kunye namalaphu adityanisiweyo womqhaphu, kwaye ngamanye amaxesha ikwasetyenziselwa ukuxutywa kwamalaphu adityanisiweyo wepolyester. Nangona kunjalo, ayinakusetyenziselwa ukwenza i-bleaching protein fibers efana nesilika kunye noboya, kuba i-sodium hypochlorite inefuthe eliyingozi kwimicu yeprotheni, kwaye yenza iintsinga zibe tyheli kunye nomonakalo. Kwinkqubo ye-bleaching, ngaphezu kokutshatyalaliswa kwee-pigments zendalo, i-cotton fiber ngokwayo nayo inokulimala, ngoko ke, kuyimfuneko ukulawula iimeko zenkqubo ye-bleaching, ukwenzela ukuba umgangatho wokubonakala kunye nomgangatho wangaphakathi ufanelekile.

I-sodium hypochlorite kulula ukwenza, ixabiso eliphantsi, i-sodium hypochlorite bleaching operation ilungile, izixhobo ezilula, kodwa ngenxa yokuba i-sodium hypochlorite bleaching imbi kukhuseleko lokusingqongileyo, ngoko ngokuthe ngcembe ithathelwe indawo yi-hydrogen peroxide.

(5) Ukucoca ngeperoxide yeHydrogen H2O2:

Ihydrogen peroxide, ekwaziwa ngokuba yihydrogen peroxide, inefomula yemolekyuli H2O2. I-hydrogen peroxide bleaching ibizwa ngokuba yi-oxygen bleaching. Ukuzinza kwesisombululo se-hydrogen peroxide kubi kakhulu phantsi kweemeko ze-alkaline. Ngenxa yoko, i-hydrogen peroxide yorhwebo iyancipha i-asidi.

Ilaphu elifakwe i-hydrogen peroxide linobumhlophe obuhle, umbala ococekileyo, kwaye akukho lula ukutyheli xa ligcinwe. Isetyenziswa kakhulu kwi-bleaching cotton fabric. I-oxygen bleaching inokuguquguquka okukhulu kune-chlorine bleaching, kodwa i-hydrogen peroxide iphezulu kunexabiso le-sodium hypochlorite, kwaye i-oxygen bleaching ifuna izixhobo zensimbi engenasici, ukusetyenziswa kwamandla kukhulu, ixabiso liphezulu kune-chlorine bleaching.

Okwangoku, indlela evulekileyo yokudibanisa umphunga isetyenziswa kakhulu kwimizi-mveliso yokushicilela kunye nokudaya. Le ndlela inezinga eliphezulu lokuqhubeka, ukuzenzekelayo kunye nokusebenza kakuhle kwemveliso, ukuhamba kwenkqubo elula kwaye ayivelisi ukungcoliseka kwendalo.

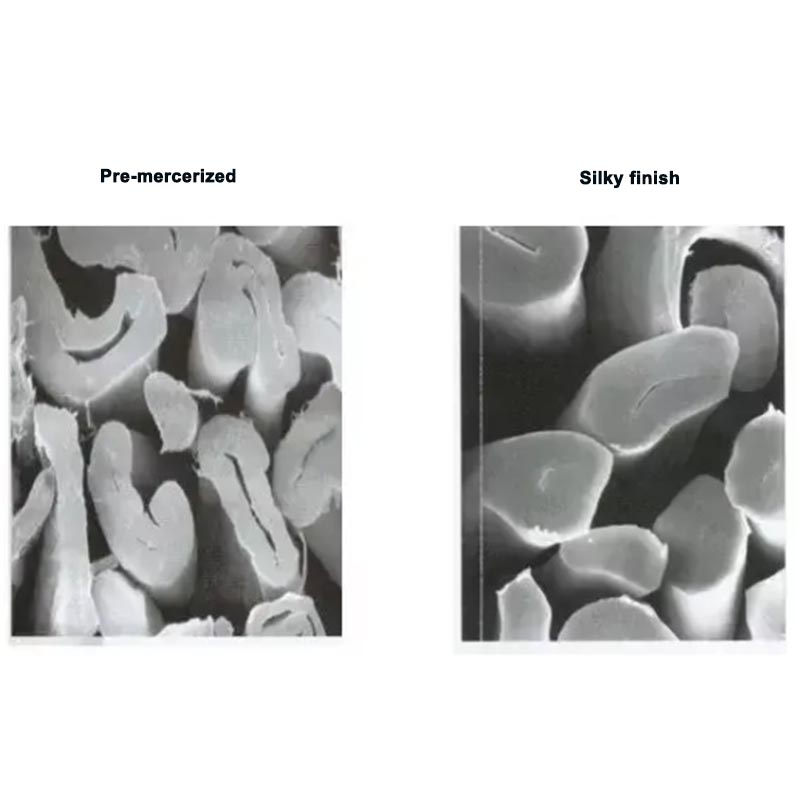

5. Mercerized (ilaphu lomqhaphu)

Iingubo eziphantsi kwemeko ethile yoxinzelelo, ngoncedo lwesoda ye-caustic egxininisiweyo, kunye nokugcina ubungakanani obufunekayo, unokufumana i-silky luster, le nkqubo ibizwa ngokuba yi-mercerization.

(1) Injongo ye-mercerization:

A.Ukuphucula i-gloss ye-gloss kunye nokuvakalelwa kwengubo, ngenxa yokuvuvukala kwefiber, ilungiselelo lefiber lilungelelene ngakumbi, kwaye ukubonakaliswa kokukhanya kuqhelekileyo, ngaloo ndlela kuphuculwe i-gloss.

B.Ukwandisa izinga lokudaya umbala emva kokugqiba i-mercerizing, indawo yefayibha iyancipha, i-amorphous indawo yanda, kwaye idayi ziyakwazi ukungena kwi-fibers, izinga lombala kune-cotton fiber ye-mercerized yanda nge-20%, kunye nokuphucula ukuphuculwa, ngexesha elifanayo ukwandisa amandla okugubungela abafileyo.

C.Ukuphucula uzinzo lwe-dimensional mercerizing baye bagqibezela isiphumo sokuyila, kunokuphelisa imibimbi yentambo, ngakumbi banokuhlangabezana neemfuno zomgangatho wokudaya kunye nokushicilela iimveliso ezinesiqingatha ezinesiqingatha. Eyona nto ibaluleke kakhulu kukuba emva kwe-mercerizing, ukuzinza kwe-deformation yokwandiswa kwelaphu kuye kwaphuculwa kakhulu, ngaloo ndlela kuncitshiswe kakhulu izinga le-shrinkage yelaphu.

6. Ukucokisa, ukucutheka kwangaphambili (ilaphu lefibre yekhemikhali)

Injongo yokucoca kwangaphambili ukucutheka ikakhulu kukususa ioyile, uludaka kunye nokungcola okubhengezwe kwilaphu (ifayibha) ngexesha lokuluka kunye nokuhanjiswa, kwaye kwangaxeshanye, ezinye ii-oligomers kwifiber zinokunyibilika ekusulungekisweni kobushushu obuphezulu. Ilaphu elingwevu kufuneka lincitshiswe ngaphambili ngaphambi kobuninzi be-alkali, kwaye izongezo ezifana ne-olein kunye ne-caustic soda kufuneka zongezwe ngokukodwa. Unyango lwangaphambili lwelaphu lefiber yeekhemikhali lwenziwa kubushushu obuphezulu kunye noxinzelelo oluphezulu lomatshini wokudaya.

7. Ukunciphisa ialkali (ilaphu lefiber yekhemikhali)

(1) Umgaqo kunye nomphumo wokunciphisa i-alkali

Unyango lokunciphisa i-alkali yinkqubo yokunyanga ilaphu le-polyester kubushushu obuphezulu kunye ne-lye evuthayo. Ifayibha yePolyester i-hydrolyzed kwaye yaphulwe yi-ester bond ye-polyester ye-molecular chain kwi-fiber kwi-sodium hydroxide isisombululo se-aqueous, kunye neemveliso ze-hydrolysis ezinamaqondo ahlukeneyo e-polymerization ziqhubeka zenziwe, kwaye ekugqibeleni i-sodium terephthalate ye-sodium enyibilikayo kunye ne-ethylene glycol yenziwa. Izixhobo zokunciphisa ialkali ikakhulu zibandakanya umatshini wokudaya ophuphumayo, umatshini wokunciphisa oqhubekayo, umatshini wokunciphisa ophakathi kwiintlobo ezintathu, ngaphandle komatshini wokudaya ophuphumayo; Oomatshini bokunciphisa abaqhubekayo naphakathi banokuphinda basebenzise i-lye eseleyo. Ukuze kuqinisekiswe ukuzinza kwembonakalo kunye nobukhulu belaphu elingwevu kwezinye iimveliso zokunciphisa i-alkali, kuyimfuneko yokongeza inkqubo emiselweyo, kwaye emva koko ungene kwinkqubo yokudaya.

Ixesha lokuposa: Feb-28-2025